Elevate Your Kiln Drying Process with Our NDKr Controls Package

The NDKR controls package was designed for kiln operators by kiln operators and is capable of being installed on any kiln from any manufacturer. Our newest platform encompasses the company’s goals of creating energy-efficient solutions for kiln drying, all while applying advanced functionality to reduce drying time without compromising quality.

Key Features

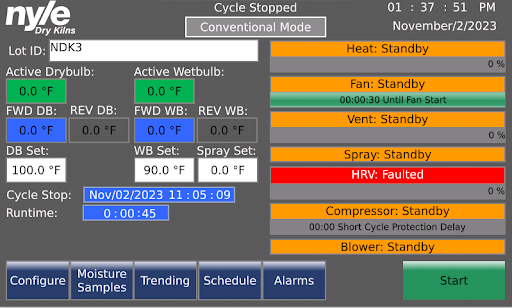

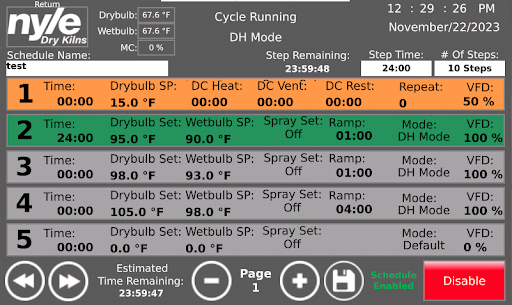

Versatile Control Modes

The NDKR system offers multiple control options, allowing for precise adjustments and customization to suit various drying needs.

Built-In Energy Management

Integrated energy management system optimizes power usage, helping to reduce operating costs while maintaining efficient kiln performance.

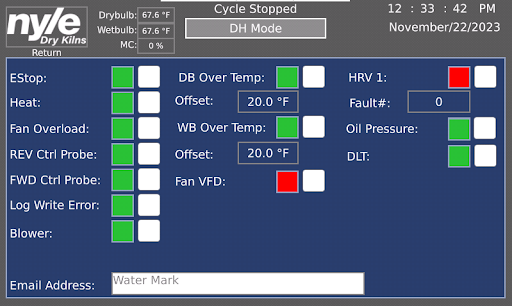

Advanced Sensor Technology

Equipped with state-of-the-art sensors for accurate monitoring of temperature and humidity, ensuring consistent and reliable drying results.

Compatible with Any Kiln

Designed to be retrofitted to any kiln, regardless of the manufacturer, providing flexibility for existing setups without needing a complete system replacement.